In the accelerated process of urbanization, the problem of left-behind children has become increasingly serious and has attracted much attention from the society. These children bear the expectations of their families, but because their parents work for a long time, they lack companionship and care. On March 11, Shandou Xinfeng Energy Power Plant Project Department, together with Xinfeng Orange County Social Work Service Center and Yongchun Culture Media, launched the "Love guard, build the future together" left-behind children visit and sympathy activities.The event opens in a warm atmosphere. The principal of the school took the stage first to explain the significance of the activity to the children, emphasizing that social care can help them overcome the obstacles of growth and pursue their dreams. At the same time, he expressed his sincere gratitude to the Xinfeng Orange County Social Work Service Center and our company for their loving support. Subsequently, the social worker representative of Orange County Social Work Service Center of Xinfeng County made a speech, saying that caring for left-behind children is a social responsibility and corporate obligation, and thanked our company for its active participation. Finally, Zhang Liwei, the representative of our company, with his kind and powerful words, encouraged the children to face the difficulties in life bravely and fearlessly, always maintain an optimistic attitude, work hard to learn knowledge, change their fate with the power of knowledge, and write their own wonderful life.At the event, our company representatives and social workers distributed carefully prepared gifts for the left-behind children, including stationery, cups and daily necessities. These gifts carry the society's deep care and expectations for the children. When the children received the gift, the eyes flashed surprise and moved, the pure smile on the face, like blooming flowers in spring, gorgeous and beautiful.For left-behind children, this public welfare activity is like a bright star in the night sky, deeply imprinted in the depths of memory, and becomes a light to illuminate their long journey in the future, giving them the strength to march forward on the road of growth. For our company, this activity has effectively transformed the values of "achieving individuals, growing enterprises, happy families, and warm society" from concept to vivid practice. The company continues the "transmission of love" with practical actions, which not only injects warmth and hope into the world of left-behind children, but also shows our company's strong sense of social responsibility and responsibility.

Recently, the selection results of the 2025 excellent QC group activity held by the Xinxiang Construction Industry Association were released, and the three results declared by our company were all awarded the first-class results of Xinxiang City, and won the excellent publisher award 2.Quality Management group (QC group) activity is one of the four pillars of total quality management, and is a very important organizational form for employees to participate in total quality management, especially quality improvement activities. Carrying out QC group activities can reflect the people-oriented spirit of modern management, mobilize the enthusiasm and creativity of all employees to participate in quality management and quality improvement, which can improve the quality of enterprises, reduce costs and create benefits, while helping to improve the quality of employees and create a vibrant and dynamic corporate culture.In recent years, our company's leading management attaches great importance to the development of QC group activities, invests a lot of human and material resources, encourages the company's project departments to actively carry out QC group activities, and has achieved fruitful results, and constantly achieve national, provincial and ministerial results.The following is the award certificate:reputation show QC team won the first prize of Xinxiang Construction Industry Association - Xinxiang Guoyue City Yufu Projectlet nature take its course QC team won the first prize of Xinxiang Construction Industry Association - Xinjiang Stone Mei Power Plant projectquality cite QC team won the first prize of Xinxiang Construction Industry Association - China Resources Puqi Phase III power plant projectYang Dawei won the excellent publisher of Xinxiang Construction Industry Association - Xinjiang Shomei Power Plant projectChen Xiangping won the excellent publisher of Xinxiang Construction Industry Association - Xinxiang Guoyue City Yufu project

On an auspicious day, everything is updated! In this hopeful and vibrant season, the construction project of the Chenxi Wet permanent living area in IMIP Industrial Park, Sulawesi Province, Indonesia, undertaken by our unit, has finally reached a milestone after countless days and nights of careful preparation and unremitting efforts. At 9:08 am on February 25, 2025 (Indonesian Central Time), the project held a grand groundbreaking ceremony, officially kicking off the construction of the project.As the first comprehensive living community project of the IMIP Park Chenxi project, our unit has faced multiple challenges since entering the site. The construction period is tight, the tropical rainforest terrain is complex, the construction window during the rainy season is short, there is a shortage of materials, water and electricity communication is not connected, and the integration of local standards is difficult... Faced with the mission of "pioneers", from overgrown weeds to blueprint layout, from technical barriers to mutual recognition of standards, the project department has set up a technical team, rotating day and night to overcome difficulties, optimizing the construction route during the rainy season and linking the supply chain system of China and India, achieving a localization rate of 60% for building materials, and pressing the "acceleration button" for project landing. The commencement of this project construction marks a solid step for our unit in the field of overseas livelihood engineering construction. After the completion of the project, it will provide modern living space, convenient living services, and high-quality catering facilities for employees in the park, helping to build the IMIP industrial park into a sustainable development industrial park with a "peaceful and happy life"Here, our project department will promote engineering construction with high standards, high quality, and high efficiency, practice the concept of green construction, and ensure the completion of the owner's goal of putting the first apartment building and canteen into use in October. We will contribute to deepening Sino Indian cooperation and contribute to the development of Henan Second Construction.

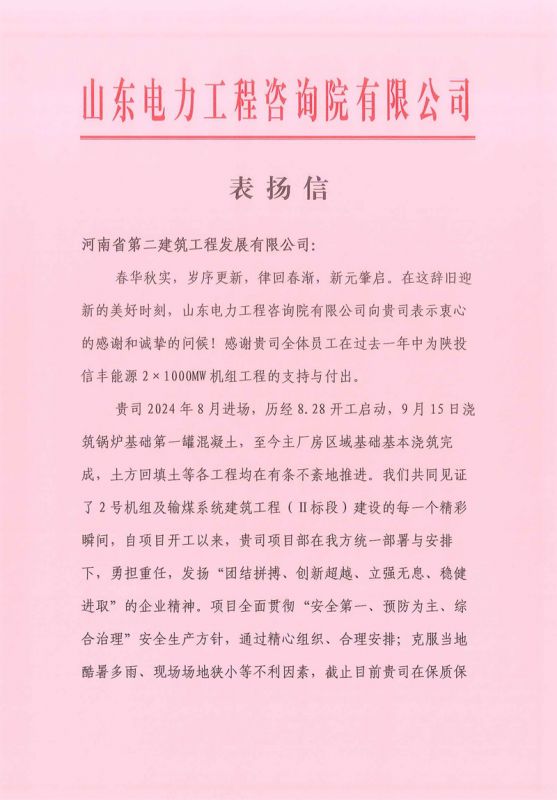

Recently, the Shantou Xinfeng Energy Project, undertaken by our company, stood out in the year-end evaluation conducted by the general contractor—Shandong Electric Power Engineering Consulting Institute Headquarters. The project management team, with its outstanding project management skills, superb craftsmanship, and efficient teamwork, overcame challenges and took on responsibilities with courage, earning high praise and a commendation letter from the general contractor’s headquarters.As one of the company’s key projects, the Shantou Xinfeng Energy Project has received significant attention since its commencement. During construction, under the unified deployment and arrangements of the general contractor, the project management team leveraged its technical expertise and management experience to overcome adverse conditions such as extreme heat, frequent rainfall, and limited space. The team meticulously organized and planned the work to ensure quality, quantity, and safety, successfully achieving all major milestones. The project has also been repeatedly recognized as an “Advanced Unit for Safety Production” and awarded “Exemplary Safe and Civilized Construction Area.”In the commendation letter, the general contractor emphasized that 2025 is a pivotal year for the Shantou Xinfeng Energy 2×1000MW Unit Project, with the primary structures set to be topped out, fully delivered, and installation work initiated. The general contractor expressed hope that the project management team will continue to embody the spirit of extraordinary dedication, resilience, and teamwork, accelerating the subsequent construction to ensure the smooth handover of the project and striving to achieve the National Gold Award for Excellent Projects.This recognition not only affirms the hard work of the entire project team but also reflects the company’s professional capabilities and high management standards. Looking ahead, our company will continue to uphold the principles of “Quality First, Safety First, and Reputation Above All.” We will strive to enhance our capabilities and service standards, providing clients with more high-quality, efficient, and satisfactory services.

Recently, a breathtaking construction feat was accomplished at the Shantou Xinfeng Energy Project site. At 4:30 p.m. on November 22, the concrete pouring of the No. 2 turbine generator base slab commenced, and after 47 hours of continuous effort, the pouring was successfully completed at 3:30 p.m. on November 24, with a total of 4,867 cubic meters of concrete poured. This extraordinary achievement is a testament to the company’s exceptional capabilities and indomitable spirit of perseverance.To ensure the success of the turbine generator base slab pouring, the project team meticulously prepared in advance. From repeated deliberations on the construction plan to the stringent selection and ample preparation of raw materials at the batching plant, every step was a reflection of immense dedication and wisdom. The engineering team thoroughly studied the construction techniques and devised a detailed pouring plan tailored to the site’s specific conditions, ensuring every step was executed with precision.At the pouring site, dozens of concrete mixer trucks operated in seamless rotation, while three concrete pump trucks extended their massive arms to continuously deliver concrete to the foundation. The construction team, including management and workers, remained steadfast on-site day and night, racing against the clock. Undeterred by exhaustion during the dead of night or the biting cold winds, they pressed on with unwavering determination. These 47 hours of continuous work tested not only their physical endurance but also their steadfast willpower and outstanding teamwork.Strict quality control was maintained throughout the process. Managers meticulously tested each batch of concrete to ensure compliance with slump and placement temperature standards. Meanwhile, department managers remained at their posts, providing unwavering support for construction safety and ensuring robust technical guidance for quality assurance.The efficient completion of the turbine generator base slab pouring has laid a solid foundation for the smooth progress of the overall project. This milestone achievement has earned high praise from the owner, supervisors, and general contractor, further enhancing the company’s reputation and garnering widespread support.Looking ahead, the construction management team and workers will continue to embody the corporate spirit of “unity and perseverance, innovation and excellence, unyielding strength, and steady progress.” With unwavering resolve and boundless enthusiasm, they will devote themselves fully to their work, pursuing practical actions and innovative solutions to ensure that the project’s quality and schedule meet contractual objectives with precision and excellence.

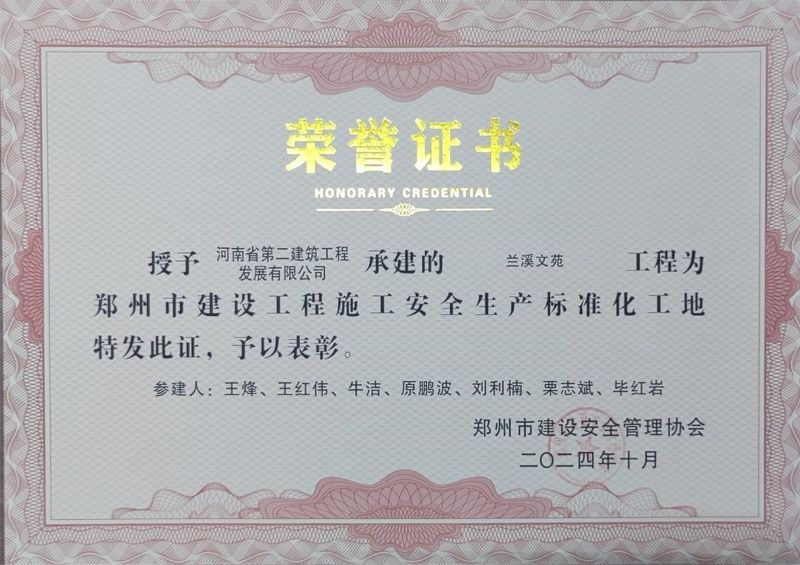

Recently, according to Document No. [2024] 17 issued by the Zhengzhou Construction Safety Management Association, the Lanxi Wenyuan Project (the EPC general contracting project for Plot 6 of Longzihu in Zhengdong New District), undertaken by our company, was awarded the title of “Zhengzhou Construction Project Safety Production Standardized Site” for the third quarter of 2024.The “Zhengzhou Construction Project Safety Production Standardized Site” is a municipal-level award for safe and civilized construction, established by the Zhengzhou Construction Safety Management Association based on the principle of strict selection and quality over quantity. This honor recognizes the company’s efforts in implementing standardized safety and civilized construction practices across its projects.Moving forward, the company will continue to uphold the safety production policy of “safety first, prevention foremost, and comprehensive management.” We will strive to enhance safety and civilized standardization management at both corporate and project levels, create more high-quality projects, and drive further achievements in safety production standardization, achieving new milestones and greater success.

At 9:58 a.m. on October 26, the Unit 3 cooling tower of the CEIC Changzhou Phase II Expansion Project, undertaken by our company, was successfully topped out.Standing proudly along the picturesque banks of the Yangtze River, this iconic structure is a testament to our dedication and expertise.The Unit 3 cooling tower features a water spraying area of 12,500 m² and a total height of 189.058 meters. Throughout the construction process, the project team clearly defined the responsibilities of every position, aiming to eliminate safety risks and quality issues from the source. Strict controls were implemented during key stages, including concrete pouring, vibration, slump monitoring, test block sampling, and formwork removal. By adopting meticulous management practices throughout the process, we not only ensured construction quality but also effectively advanced the project schedule.Despite the complex geological and climatic conditions at the project site, including frequent rainy weather, and the challenges posed by tight deadlines and heavy tasks, the project team, with strong support and assistance from company leadership, demonstrated perseverance and teamwork to overcome numerous difficulties. This milestone achievement marks a significant victory for the team.The successful topping out of the Unit 3 cooling tower lays a solid foundation for the construction of Unit 4. Moving forward, the project team will continue to work diligently, meticulously organizing every task to ensure that all on-site plans are completed on schedule. Efforts in safety and quality management will also reach new heights.

At 8:17 a.m. on October 6, the 180-meter sleeve chimney of the supporting power station project of Xinjiang Yihua Chemical Co., Ltd. undertaken by our company was successfully capped, and the owner's unit, supervision unit and project management team gathered at the scene to witness this important moment.Since the start of construction on August 15, 2023, the 180-meter sleeve chimney project of Xinjiang Yihua Chemical Co., Ltd. supporting power station project has made concerted efforts to overcome various difficulties, give full play to the sense of initiative, actively communicate and coordinate with the owner and the supervision unit, and strive to promote the development of the project.Since the start of the project, with the high support and concern of the company's leaders, the project personnel and labor-related management personnel have always adhered to the company's enterprise spirit of "unity and hard work, innovation and transcendence, strong and unyielding, steady and enterprising", and actively and actively promoted the construction of the project with the principle of "building a quality and integrity system, building a safe and healthy environment, creating high-quality projects, and satisfying the owners", and won the high evaluation and recognition of the owners and the establishment units.In view of the follow-up installation work, the project has been Secondary planning and deploying, and is currently progressing in an orderly manner, and all the staff of the project will continue to maintain a modest and cautious, steady and enterprising work attitude, and strive for high quality, high standards and satisfactory delivery of a satisfactory answer to the owner and our company.

At 09:57 a.m. on October 07, with the completion of the pouring of the last concrete of the intercooling tower wall, the intercooling tower of Unit 1 of Xinjiang Zhongneng Shitoumei 2×1 million kilowatt coal-fired power project was successfully capped.The intercooling tower of Unit 1 was started on July 25, 2023, the pouring of the ring foundation was completed on October 12, 2023, and the hoisting of the X-inclined pillar of the steel pipe of the intercooling tower was completed on November 18, 2023. The first mold of the cylinder wall ring beam was poured on March 30, 2024. The wall of the intercooling tower is a thin-shell reinforced concrete structure, the height of the intercooling tower is 205m, the diameter of the outlet of the cylinder wall is 105.20m, the throat height: 150.675m, the throat diameter is 99.20m, the height of the air inlet is 33.30m (the bottom of the steel ring beam), and the diameter of the air inlet is 119.917m (the inner mold of the steel ring beam). The cylinder wall is supported by 46 pairs of concrete-filled steel tube X pillars.Since the start of the project, the project department has actively overcome the difficulties of strong winds, sandstorms, bad weather, scorching heat, short annual effective construction period, and strong construction professionalism in Hami area, and the cylinder wall project has gone through 210 calendar days (including 53 days of windy weather and 157 days of actual effective construction), and completed the project milestone node project with high quality, laying a solid foundation for subsequent installation.During the implementation of the project, in strict accordance with the principle of "advanced planning, process control, and one-time excellence", the construction safety and quality of the intercooling tower wall are always put in the first place, and each team is organized to optimize the construction plan, strengthen the safety management of the construction site, strictly implement the "safety regulations" and the "15 high-voltage lines" of Xinjiang Zhongneng Power Company, and implement the grading and acceptance system, and focus on the key quality control points and processes to ensure the safe and smooth completion of the construction of the intercooling tower.The successful capping of the intercooling tower of Unit 1 embodies the excellent quality pursuit and excellent professional skills of our company, and the project management team will continue to be down-to-earth, forge ahead, and constantly climb the peak of construction technology to ensure the smooth progress of the project.